Optical Monitor System

Optical monitoring has become a critical technology for creating high-quality interference optical coatings.

Innovative Technology

Optical monitoring serves as an advanced solution for overseeing deposition processes. This innovative technology provides exceptional precision, allowing for the proactive adjustment of critical process parameters to ensure superior results.

Optimized Process Management

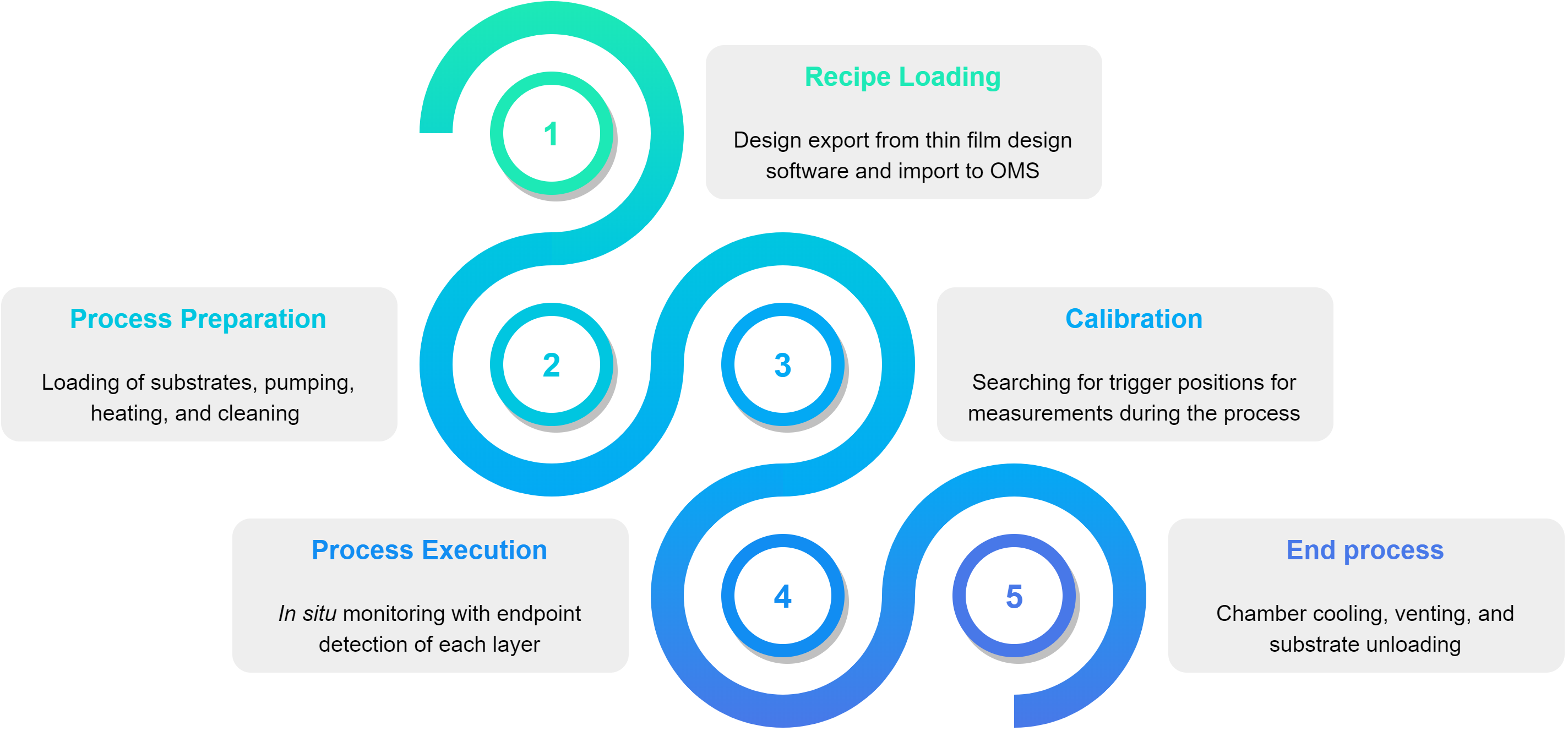

With the needs of our clients and end-users at the forefront, we designed an intuitive method for optical coating fabrication. The application of interference coatings has never been more straightforward. Our system enables the achievement of exceptional results with minimal effort, thereby making complex processes attainable for a diverse range of specialists.

Coatings Mathematics

Our system presents a multitude of monitoring strategies, leading to significant improvements in product yield and process tolerance. An advanced algorithmic calculation automatically defines the deposition endpoint based on optical signal intensity data, thereby ensuring superior accuracy and repeatability.

Measurement & Analysis Platform

The Insoptics software platform provides support for monochromators, spectrometers, and spectrographs. This comprehensive compatibility facilitates the execution of any monitoring strategy essential for fabricating a precisely defined coating.

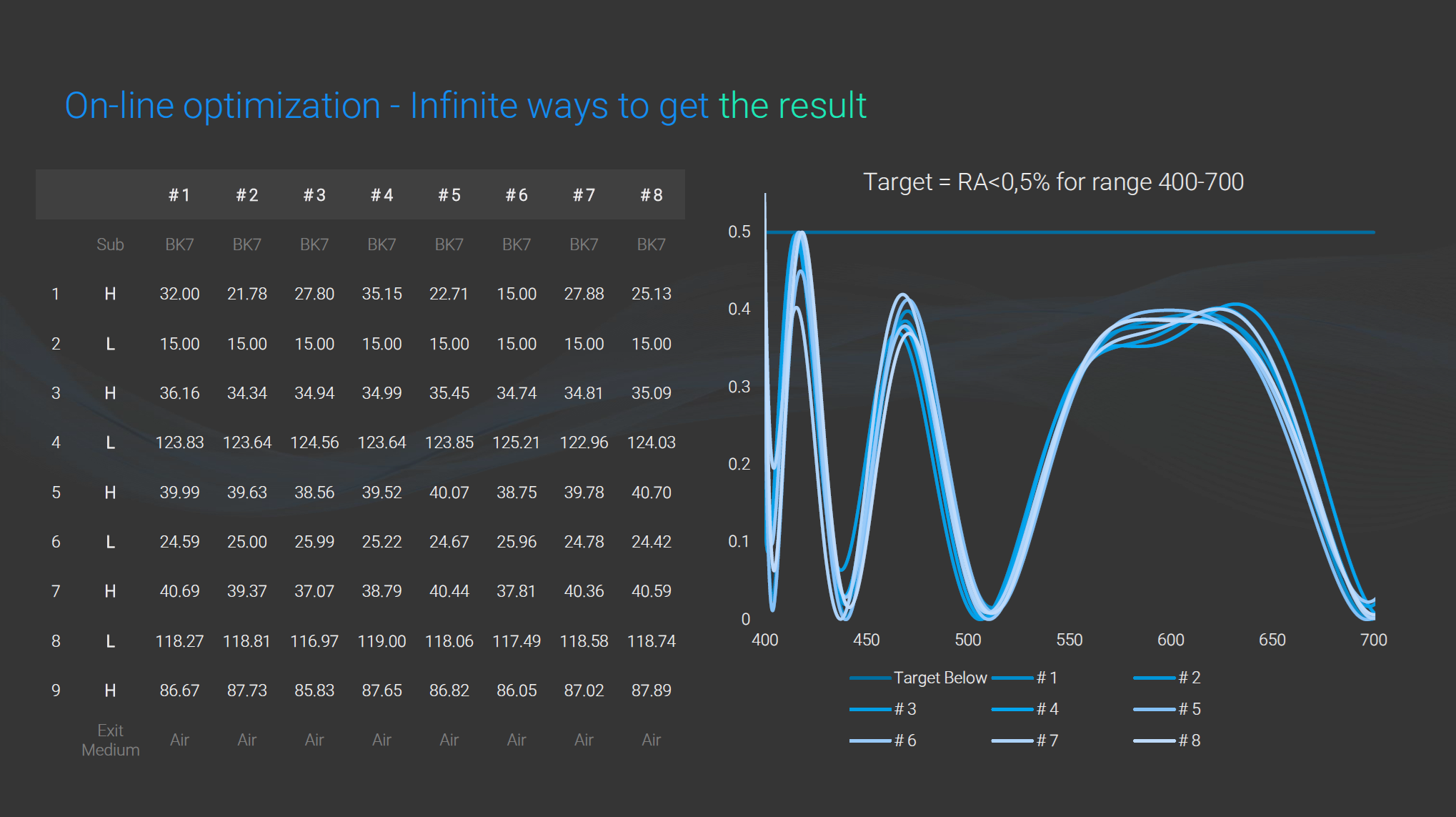

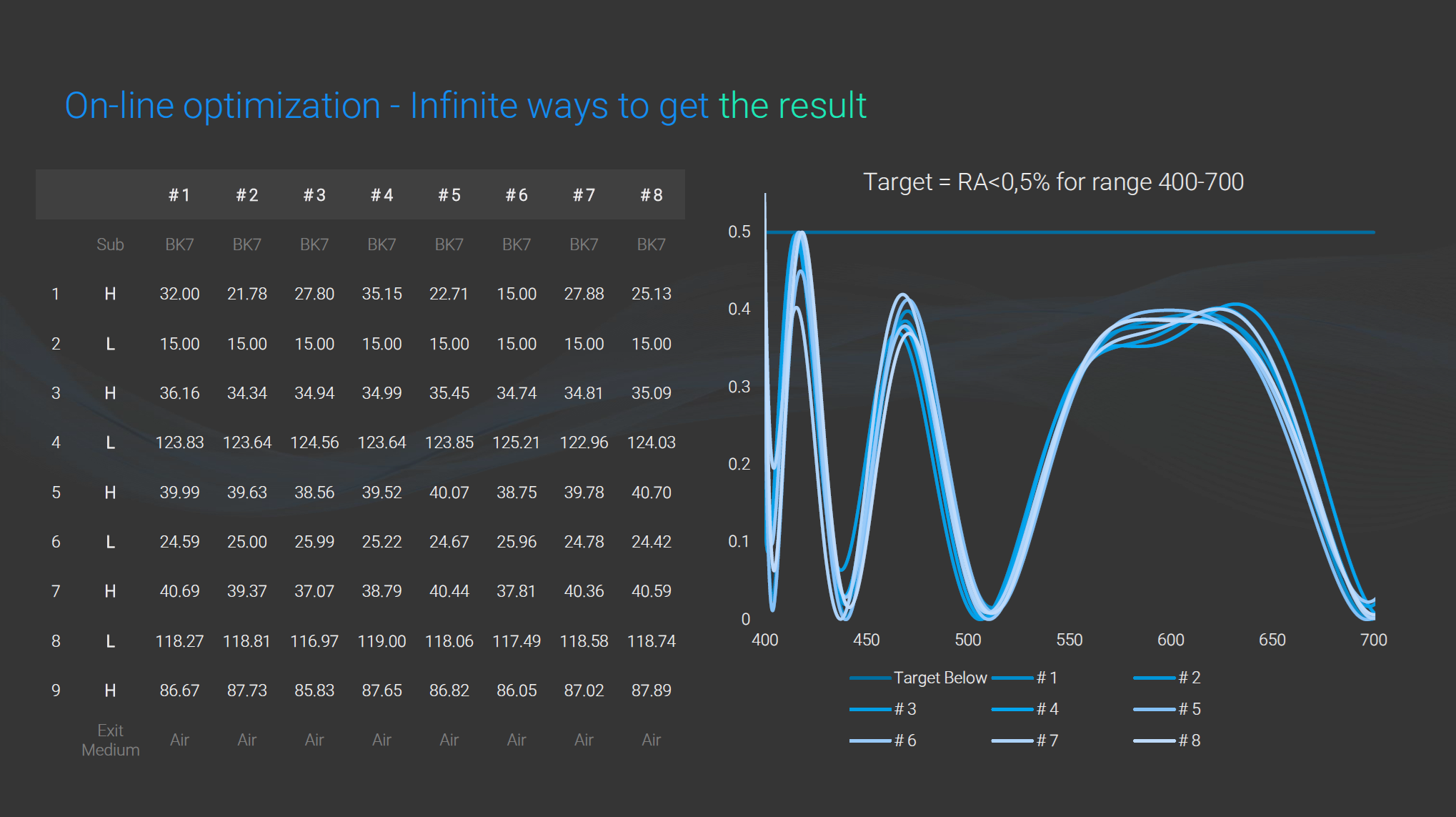

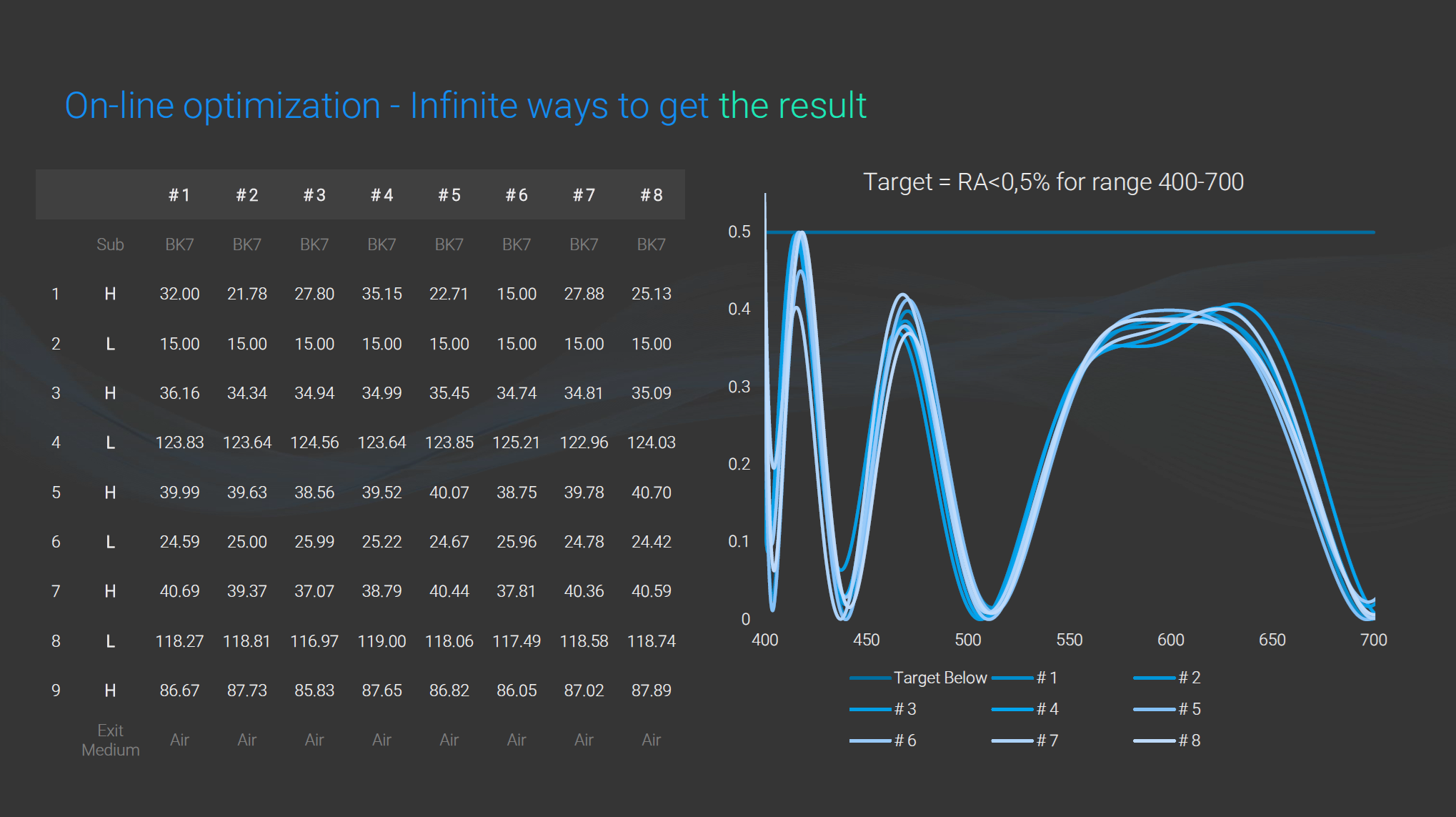

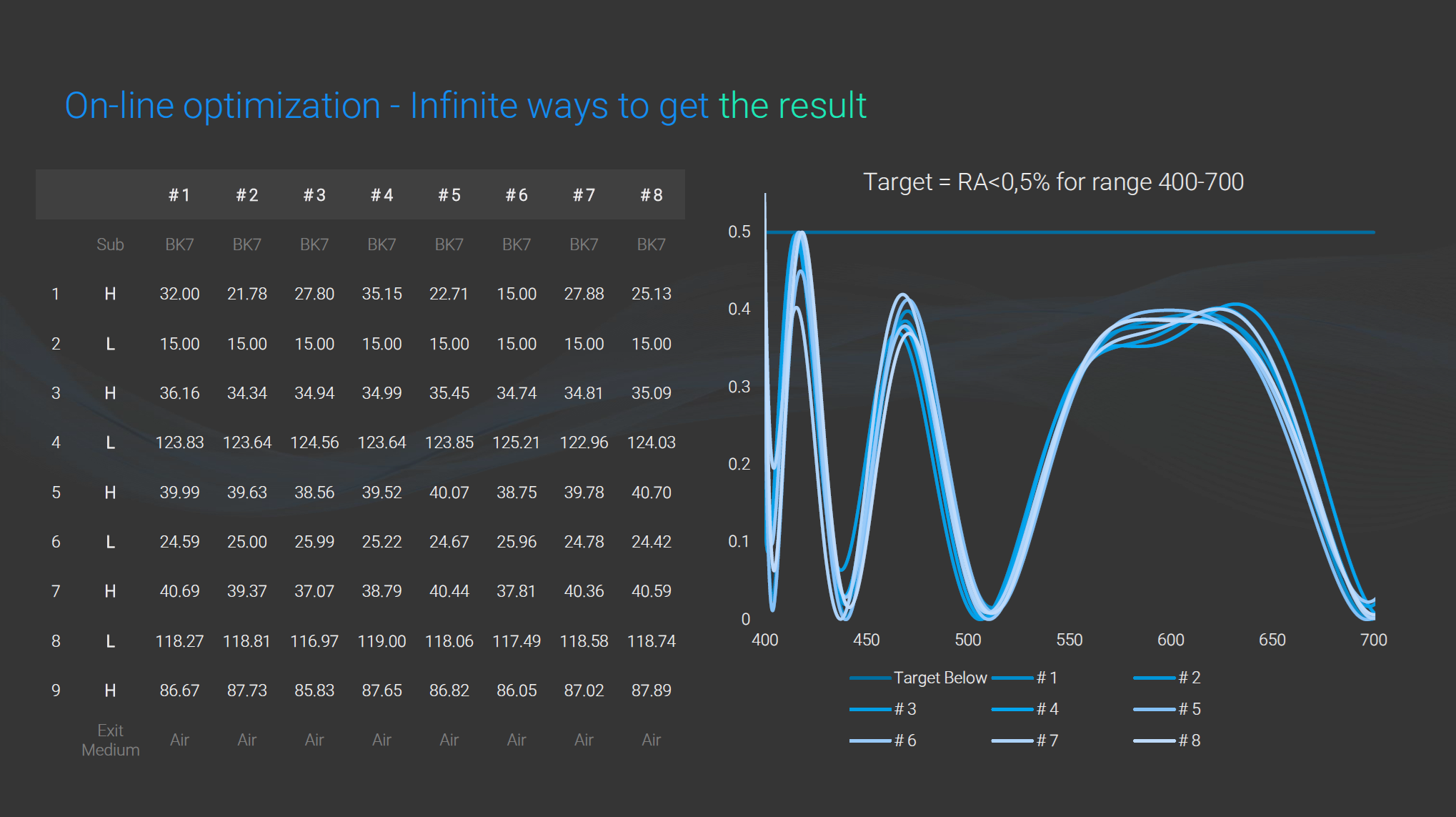

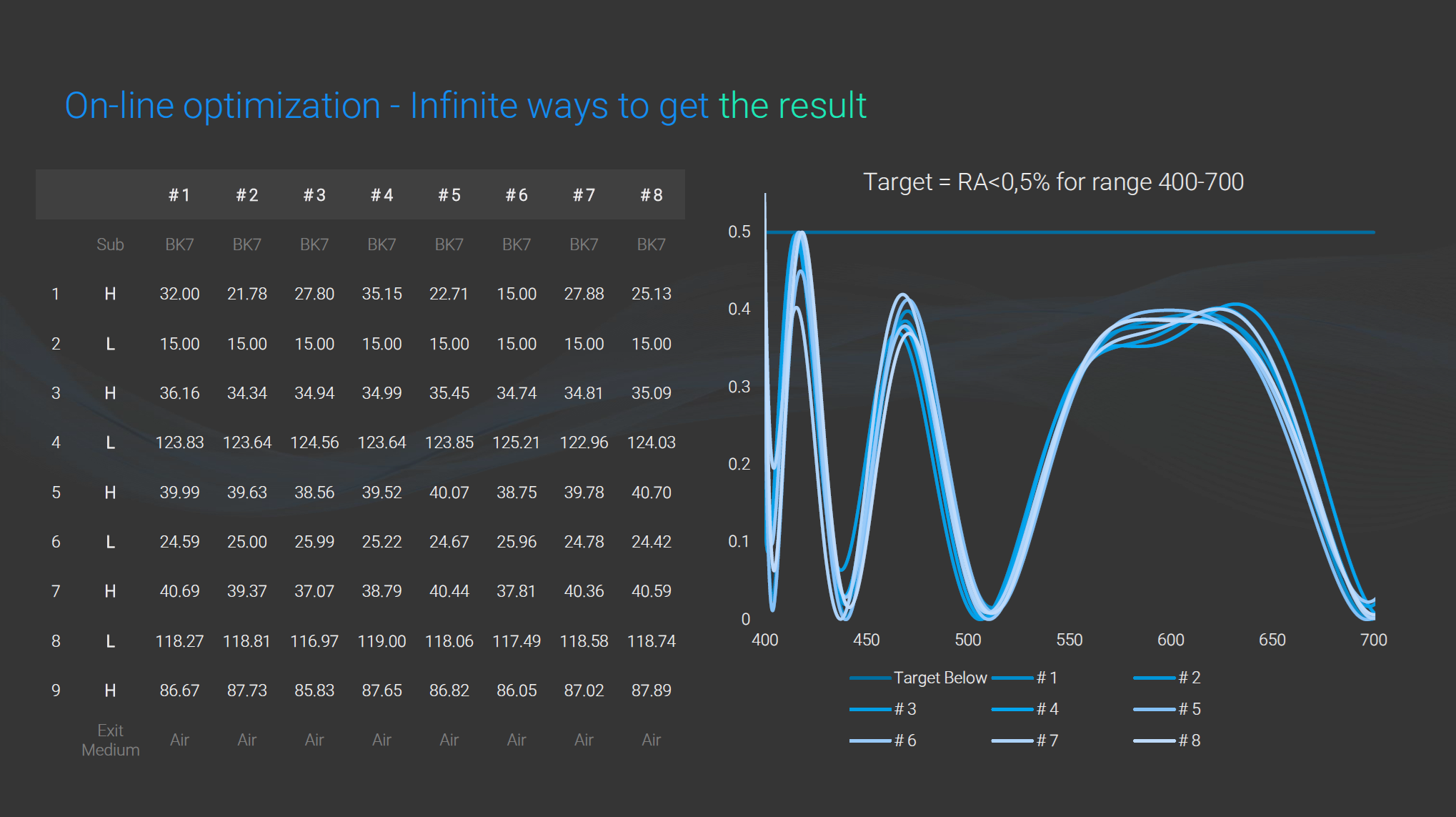

Real-Time Optimization

The Insoptics optical monitor features an integrated software engine capable of in-situ optimization for optical coating deposition. This delivers exceptional control, allowing you to achieve superior deposition results in real time.

Integration

The Insoptics software is developed for seamless integration with virtually any deposition equipment, spanning from batch systems to fully automated in-line solutions. This provides unparalleled flexibility for a wide array of optical applications.

Learn how our products can help you achieve more.

Contact Us

MultiWave

Deposition Control Application: Utilizes an innovative and unparalleled mathematical framework, offering an intuitive user interface and extensive compatibility with nearly all global deposition equipment.

Read More

Hardware platform

A modular platform featuring modern components designed to house our boards, ensuring high system stability and versatility across various configurations.

Read More

Measurement devices

High-precision monochromators, spectrometers, and spectrographs, specifically adapted for controlling optical deposition processes.

Read MoreSpecification

| Monochromator (Single Wavelength) | Spectrometer (Broadband) | Spectrograph (Mixed) |

|---|---|---|

| 380-1100 [nm] | 380-1100 [nm] | 380-1100 [nm] |

| 200-1100 [nm] | 200-1100 [nm] | 200-1100 [nm] |

| 380-1650 [nm] | 380-1650 [nm] | |

| 380-2500 [nm] |

The following control types are available:

- Intermittent: Transmission

- Continuous: Transmission, Reflection, Backside Reflection

| Disc | Dome | Drum |

|---|---|---|

|

|

|

| Parameter | Value |

|---|---|

| Thin-film Design Software |

|

| Data Transfer |

|

| Halogen Lamp Source | DC Stabilization, Health Monitor |

| Deuterium Light Source | Health Monitor |